- You have no items in your shopping cart

- Subtotal: $0.00

[ad_1]

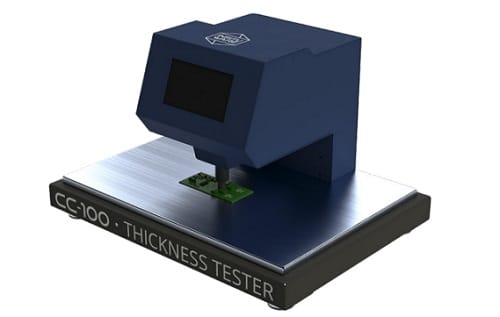

- The CC-100 conformal coating thickness tester can measure the thickness of wet and dry conformal coatings.

- The CC-100 can measure the thickness of the coating directly on the production board in less than 5 seconds.

The CC-100 from Insituware LLC is a Conformal Coating Thickness Tester measuring device. The CC-100 is able to measure the thickness of wet and dry conformal coatings directly on production boards in less than 5 seconds. The non-destructive and non-contact testing method is fast and provides accurate results to help electronics manufacturers meet the requirements for quality standards.

According to the company, the CC-100 Thickness Tester uses a chromatic confocal measurement principle to determine the thickness of transparent layers. The internal beam splitter uses white light to produce a spectrum of monochromatic light at different distances from the optical sensor. The light reflected from the top and bottom of a conformal coating layer corresponds to the intensity peaks of the respective wavelengths of light. The CC-100 uses the optical properties of a coating to determine the thickness of a conformal coating layer.

Dry Conformal Coating Thickness Measure the dry thickness of conformal coatings to verify against the requirements of IPC-A-610. The CC-100 is easy to operate, therefore, expert operator technique is not required for accurate and consistent thickness measurement. The machine can test a variety of materials including acrylic, polyurethane, silicone, epoxy, and UV.

Features of the CC-100:

- Fast Measurement: Less than 5 seconds of measurement time

- Measure the Actual Assembly: Non-destructive and non-contact technology eliminates the need for coating test coupons

- Easy operation: Skilled operator technique is not required for accurate and consistent thickness measurement

- Statistical Process Control: Local and cloud data storage for process tracking and control

- Multi-Coating Support: Acrylic, Polyurethane, Silicone, Epoxy, and UV

[ad_2]