- You have no items in your shopping cart

- Subtotal: $0.00

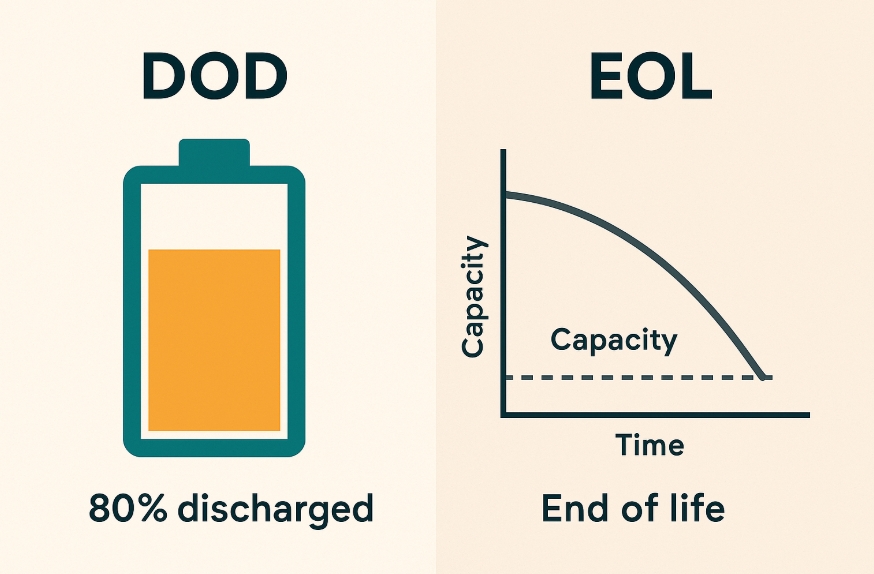

DOD vs EOL of Battery: When it comes to energy storage systems—especially lithium-ion batteries—two technical terms often come up: DOD (Depth of Discharge) and EOL (End of Life).

At first glance, they might seem similar. But in reality, they define two very different aspects of a battery’s life, performance, and long-term safety. Ignoring the distinction could cost you not just money, but also efficiency, reliability—and even safety.

Let’s break down these terms in plain, powerful words.

✅ What is DOD (Depth of Discharge)?

Depth of Discharge (DOD) refers to the percentage of a battery’s total capacity that has been used.

🔍 In Simple Words:

If you have a 100Ah battery and you use 80Ah, the DOD is 80%. The remaining 20% is State of Charge (SOC).

📊 Common DOD Values in Use:

- 100% DOD – Full discharge (rarely recommended)

- 80% DOD – Common for LiFePO4

- 50% DOD – For extended lifespan in lead-acid

- 10–30% DOD – For mission-critical or long-life applications

🚫 What is EOL (End of Life)?

End of Life (EOL) indicates the point where a battery can no longer deliver its rated capacity effectively—even though it may still work.

🔍 In Simple Words:

A battery reaches EOL when its usable capacity has dropped below 60–80% of the original, depending on design and application.

⚠️ Key Indicators of EOL:

- Capacity drops to 60–70% of original

- Voltage fluctuations increase

- Internal Resistance (IR) increases

- Longer charging time

- Faster self-discharge

📌 DOD vs EOL: Key Differences at a Glance

| Parameter | DOD (Depth of Discharge) | EOL (End of Life) |

|---|---|---|

| Definition | How much energy has been used | When the battery can no longer function as designed |

| Unit | Percentage (%) | Percentage of original capacity left |

| Impact on Lifespan | Higher DOD reduces lifespan | Reaching EOL ends the battery’s usable life |

| Usage | Daily operation and cycle calculation | Replacement decision and performance planning |

| Who Needs to Care? | Users, Installers, BMS Programmers | Buyers, Project Planners, Maintenance Teams |

| Measurement Time | Real-time during every cycle | Cumulative over the battery’s total usage |

⚙️ Why DOD Matters in Real-World Battery Usage

Every battery has a DOD limit beyond which using it shortens its lifespan.

Example:

- A LiFePO4 battery may offer:

- 6000 cycles at 80% DOD

- 3000 cycles at 100% DOD

Takeaway: Lower DOD = longer life.

So if you’re designing a system to last 10+ years, operating at 70–80% DOD can help you stretch your investment further.

⏳ Why EOL Must Not Be Ignored

Many users mistakenly assume that a battery is usable until it stops working completely. That’s dangerous and misleading.

Why?

- Once a battery reaches EOL, even if it “works”, it may deliver only 50–60% of its rated energy.

- This can underpower your application, lead to voltage instability, and stress the other system components.

Ignoring EOL risks:

- Increased fire hazards (especially in lithium chemistries)

- Sudden system failures

- Oversizing of backup generators due to unreliable energy delivery

💡 Relationship Between DOD and EOL

Now comes the real question: How does DOD affect EOL?

Direct Impact:

- The deeper you discharge the battery (higher DOD), the faster it reaches EOL.

- Each deep cycle causes microscopic stress on the electrodes, leading to capacity loss.

Battery Management Strategy:

- Set DOD limits (e.g., 80%) in your BMS to extend the time before EOL.

- Monitor capacity degradation monthly or quarterly to predict EOL.

🔐 Real-World Use Case: Why This Knowledge Saves You

Scenario:

You’re sourcing a 100kWh LiFePO4 energy storage system for a residential project.

- The supplier promises 6000 cycles at 80% DOD

- After 10 years, battery capacity is expected to drop to 70%—its EOL point

If you didn’t factor in EOL, you’d wrongly assume the battery will deliver 100kWh for 10 years.

But in reality, the client will start seeing reduced backup time after year 6 or 7, leading to complaints or system redesigns.

⚠️ DOD vs EOL of Battery: Common Myths Debunked

❌ Myth: “You can use 100% of a battery all the time.”

➡️ Truth: Doing so kills the battery faster. Only specific chemistries and applications support this with proper cooling and control.

❌ Myth: “Battery is dead only when it stops working.”

➡️ Truth: No, EOL is when capacity drops below usable limits, which happens much before it “dies.”

❌ Myth: “EOL can be ignored if the system works.”

➡️ Truth: It puts the whole system at risk, including inverters, PCS, and even safety.

🛠️ Tips for Users and Project Managers

- Always ask your supplier for DOD cycle data (e.g., cycle life vs DOD chart).

- Check warranty terms: Does it end at 70% or 60% capacity?

- Include EOL threshold planning in your project cost forecast.

- Use a BMS that logs depth of discharge and gives EOL prediction alerts.

📣 Final Thoughts: Protect Your Investment

Whether you’re sourcing for homes, C&I rooftops, microgrids, or EV infrastructure—understanding DOD vs EOL isn’t optional anymore.

🔋 A battery isn’t just a box of power.

It’s a lifeline for energy security, uptime, and performance.

Knowing how much energy you can use (DOD) and when you need to replace the battery (EOL) gives you control, safety, and long-term value.

❓FAQ: DOD vs EOL of Battery

Q1: Can I use 100% DOD in LiFePO4?

A: Technically yes, but it drastically reduces cycle life. 80% is recommended for balance between usage and lifespan.

Q2: How do I know when my battery has reached EOL?

A: If your battery only holds 60–70% of its original capacity despite being fully charged, it’s likely at EOL.

Q3: Do BMS systems track EOL?

A: Yes. Modern BMS systems can estimate remaining useful life based on charge-discharge cycles and capacity degradation.

Q4: How to increase EOL duration?

A: Avoid deep discharges, maintain optimal temperature, and regularly monitor performance.

Q5: Does temperature affect DOD and EOL?

A: Absolutely. High temperatures accelerate chemical degradation and shorten both cycle life and EOL.