- You have no items in your shopping cart

- Subtotal: $0.00

[ad_1]

Researchers dive into the molecular battery space to improve performance as well as battery life.

Electronics is the study of the movement of electrons in semiconductors and conductors. Every electronic device from a tiny microchip to a supercomputer, functions because of these micro particles. Considering a battery in this case, the charging and discharging of ions is what drives the whole concept. After a few hundred charging cycles, you’ll notice—your phone, laptop or electric car battery drains more quickly. Eventually, it stopped holding a charge.

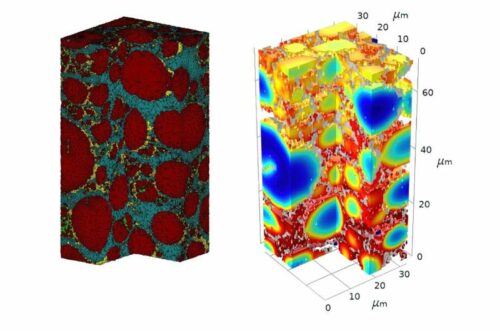

Researchers at the University of Chicago’s Pritzker School of Molecular Engineering (PME) have now used a combination of high-powered electron microscopy and computational modeling to understand, at the atomic level, exactly what happens when lithium-ion batteries are damaged. Their research points to a way to design longer-lasting lithium-ion batteries—by focusing on an often-overlooked structural component, the carbon binder domain (CBD).

When a lithium-ion battery is charged, lithium ions move from a positively charged cathode to a negatively charged anode. To release energy, those ions flow back from the anode to the cathode. Throughout charging cycles, the active materials of the cathode and anode expand and contract, accumulating “particle cracks” and other physical damage. Over time, this makes lithium-ion batteries less efficient.

The kinetics of a thick electrode is very different from a thin electrode. Degradation is actually more severe with thicker, higher energy electrodes, which is a struggle for the field. The researchers believe that it is also more difficult to study thicker electrodes quantitatively. They used Plasma focused ion beam-scanning electron microscopy (PFIB-SEM) to collect data on the new cathode as well as one that had been charged and discharged 15 times. With data from electron microscopy experiments, the team built computational models that describe the process of battery degradation.

The researchers discovered that the differentiation between the battery’s components encouraged many structural changes. Electrolyte corrosion occurs more often in a thin layer on the surface of the cathode. This top layer therefore creates a thicker resistive layer, which causes the bottom layer to expand and contract more than other parts of the cathode, leading to faster degradation.

With their cathode model, Meng’s group studied how tweaks to the electrode’s design could affect its degradation. They show that changing the network structure of CBD helps prevent the deterioration of contacts between CBD and active materials, making batteries last longer—a hypothesis that engineers can now follow. in physical experiments.

Reference: Minghao Zhang et al, Coupling multiscale imaging analysis and computational modeling for understanding thick cathode degradation mechanisms, Joule (2022). DOI: 10.1016/j.joule.2022.12.001

[ad_2]

Source link

[…] common problem encountered with LiPo battery puffing or is swelling. In this blog post, we will explore what causes LiPo batteries to puff and how to prevent it from […]