- You have no items in your shopping cart

- Subtotal: $0.00

[ad_1]

Every electronic device contains a semiconductor chip that must have compliance certifications. But EMI/EMC contributes to a significant number of compliance failures in electronic devices. That’s the problem SimYog aims to solve.

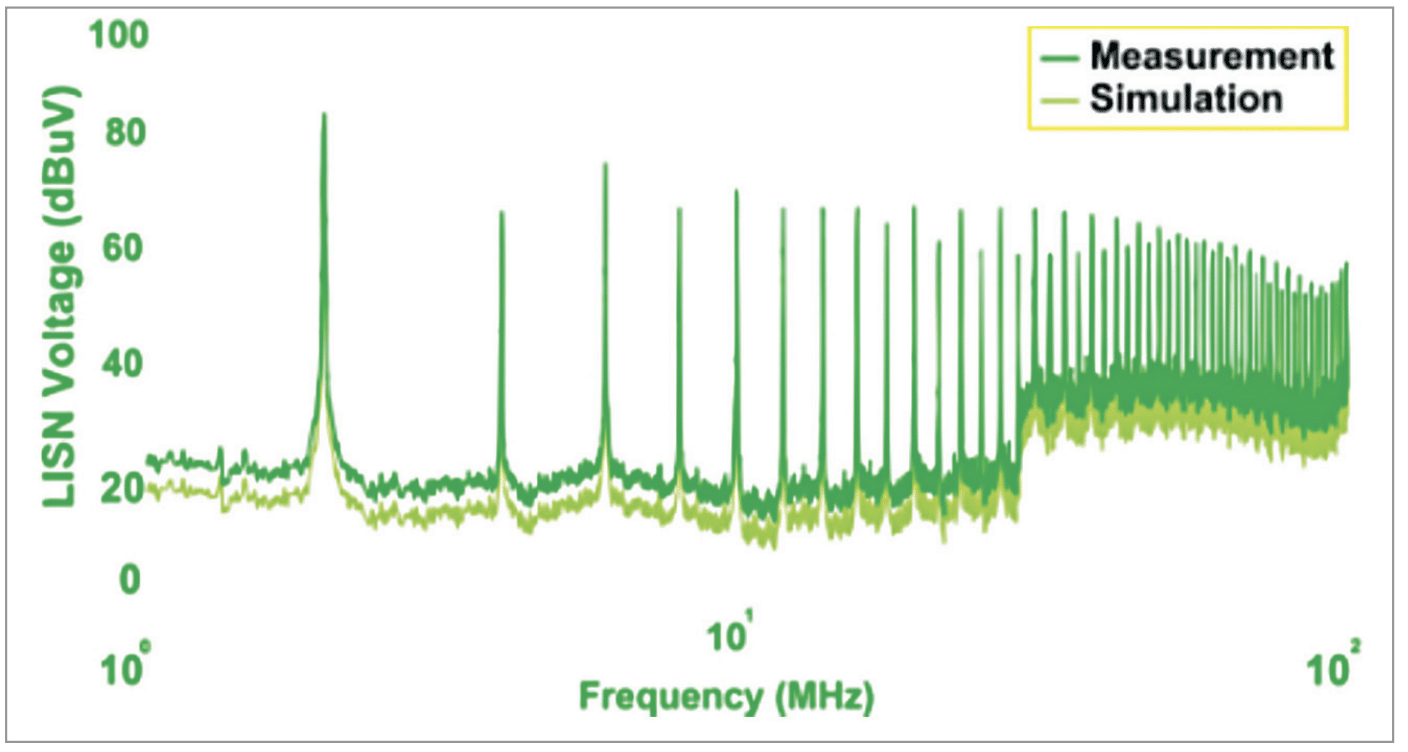

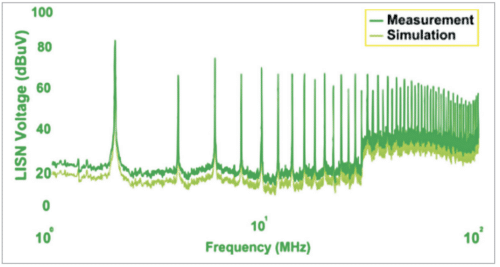

Virtual lab simulations versus physical lab measurements. SimYog simulation achieves performance accuracy through a combination of physics and data science (Credit: SimYog Technologies)

SimYog Technology, a company based in Bengaluru and Austin (USA), is a spinoff from IISc. Founded in 2017, SimYog’s mission is “Agile for Hardware.” “We want to help startups and electronics design companies,” said Dr Dipanjan Gope, CEO of Simyog Technology and Associate Professor at IISc. “We provide design tools and simulation tools that help develop hardware.”

Today, the number of electronic and electrical components in most systems is growing faster than ever. A next generation car or a drone is like a next generation PCB! Therefore, the way electronics are designed is also changing. If you look at the automotive industry, a lot of electronics are packed close together. This increases the chance of them interfering with each other.

The noise generated by each of these components can affect and impair the performance of the others. It is therefore important to ensure electromagnetic compatibility. It is important to ensure that these components pass the electromagnetic compatibility (EMC) test the first time.

The problem with EMC testing is that it is handled at the physical stage. Once you have the hardware, you can simply take it to the laboratory and test it. Since the hardware is only available in the final stages of the design cycle, it can be very difficult and time-consuming to adjust the hardware if the test fails.

Compliance-Scope, a tool designed by SimYog, enables a designer to test EMC in the early design stages. “If you’re testing at an early stage, there are ways to fix the problem and it’s much cheaper. There’s no need to cancel projects or make a lot of design changes,” explained Dr Gope.

Compliance-Scope is a virtual EMI/EMC laboratory that allows engineers to perform such tests using only design files rather than actual hardware. “It shows some diagnostics so the designer can use it to reduce emissions,” said Dr Gope.

The company uses a special approach with two parts—one based on physical science (computations, circuits, and electromagnetics) and the other based on data science. With these two pillars combined—data science and physical science—it is possible to predict how a device will behave in the lab.

“We offer our products in the cloud. Now, we are in the automotive sector, but we want to use our tools in the IT and aerospace sectors as well,” said Dr Gope. “The journey continues!”

[ad_2]

Source link

[…] Threat Scanner comes into the picture. Redinent’s threat scanning platform is a profound technological innovation that opens up a new business strategy and opportunity around IoT device security. The technology is […]